How about trying something new?

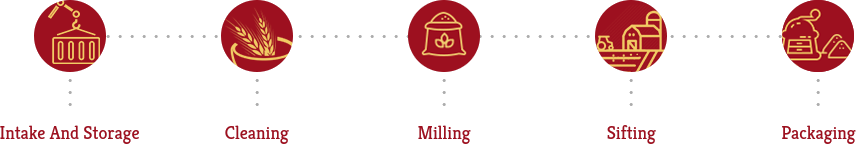

How We Bring The Best Quality Food To Your Dining Table

At the Factories

Our experts examine the quality of wheat grains.

This lab-oriented examination is effective to identify even the slightest flaws which are not noticeable with the naked eye.

Only the best-quality is processed ahead and grains with the slightest imperfections are removed.

We do not use any chemicals or hazardous activities. Even the small and light particles that flow in the air and collected by the filter bags of the

Buhler Swiss Technology system. The collected impurities like stones, soil etc are used for the land development of the factory area.

Storing Process

After the comprehensive refining, the wheat grains are stored in the large compact containers called Silos.

At the appropriate time, they are shifted to the flour mill for production procedure.

We do not use any chemicals or hazardous activities. Even the small and light particles that flow in the air and collected by the filter bags of the

Buhler Swiss Technology system. The collected impurities like stones, soil etc are used for the land development of the factory area.

|

Refining & Storing process |

Touch Free Process

The production process is completely human touch-free. We use the latest machines for the process.

- Drum Sieves are used to separate the bigger impurities like mud balls and jute threads while Separators are used to eliminate lighter particles.

- Powerful magnets are used to remove the ferrous impurities.

- Stones are removed by Destoner and Scourer is used to clean the upper part of wheat.

|

Cleaning Process |

Milling & Sifting

Now the process of milling and sifting starts.

The high capacity sifter machine is designed to refine and grading the floury products in wheat. It moves with a specific speed to get the fine sifted products.

The clean flour gets processed in the machine and comes out with finest Maida, Rava and Sooji separately.

|

Milling & Sifting process |

Chakki Atta Mill

The Chakki Atta Mill has stone grinders which are hand chiselled. Unlike the ones at home, this mill is really big!

After each round of grinding, the stone is re-chiselled to get the required quality product. Anything less than 100 percent is sent back for round two.

At the end, the flour is sifted in a circular motion at right speed and gets separated to create Atta and bran.

|

The Mill |

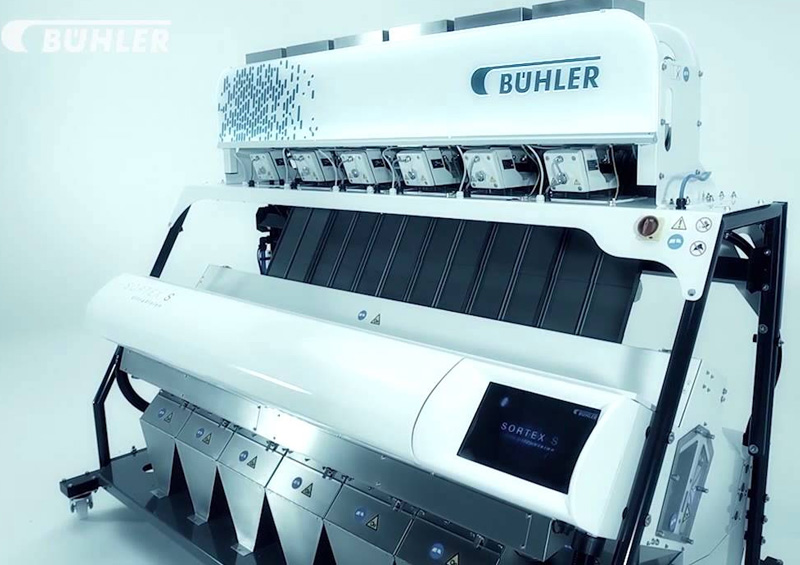

Buhler Technology

Buhler system offers a wide range of solutions for sifting and grading floury products in a minimum space of wheat, rye, maize (corn) and durum as well as in sorting different bulk products. This advanced process ensures high-quality atta flour with traditional taste and standards.

The innovative PESA MillTM used in the production process is highly efficient and it can perform the workload of 20 traditional chakki mills. Designed to deliver flawless atta flour, it uses high compression grinding that saves 10% energy and gives higher yield. It also requires less maintenance than the traditional stone mills.

|

Our Technology |

Our Products

Sealed packets are then transferred to defined godowns, distributors and then to retailers.

This is how Samrat products reach your doorstep with the use of finest raw material and world class technology.

And that’s how we ensure we bring the finest food to your dining table everyday!